Improve reliability: PCBA can accurately place electronic components, thereby improving the reliability of the final product. Using an automated assembly process, PCBA can also help reduce the risk of human error and improve overall quality.

Improve efficiency: PCBA can achieve rapid prototyping and production of circuit boards, thereby helping to simplify the manufacturing process. Automated assembly processes can also reduce the time and labor required to produce finished products.

Reduce costs: PCBA can help reduce the overall cost of electronic product manufacturing by minimizing defects and the number of rework required. Automating the assembly process can also reduce labor costs and improve production efficiency.

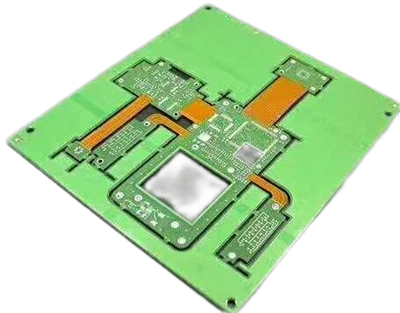

Enhanced performance: PCBA allows the use of advanced components and materials, which can improve the performance of the final product. For example, high-density PCBA can help increase the processing speed and power of electronic devices.

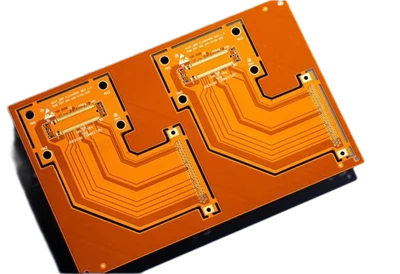

Greater design flexibility: PCBA allows the use of a variety of components and materials, providing designers with greater flexibility in product design. For example, hybrid technology PCBA uses both through-hole and surface mount components on the same circuit board.