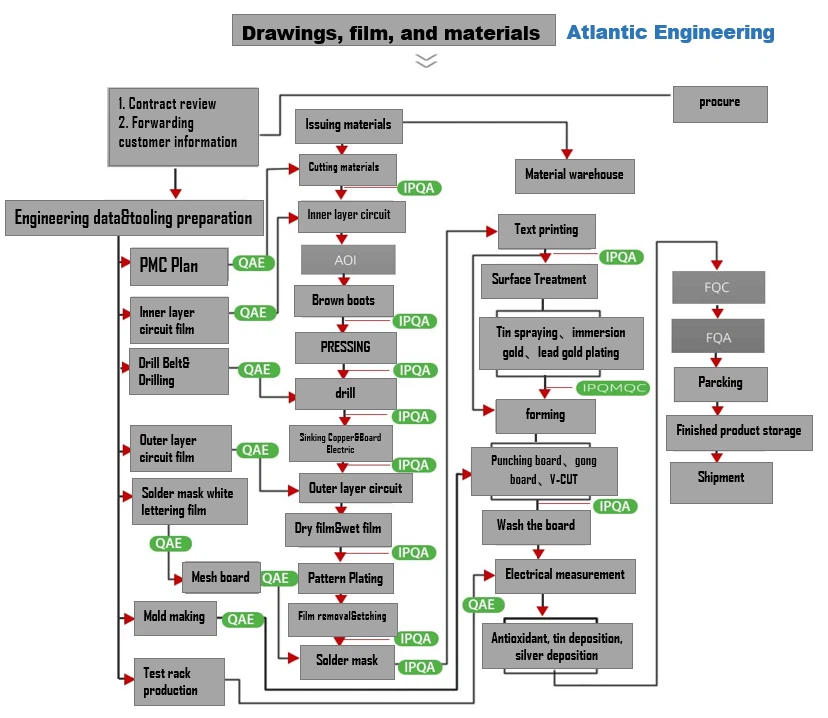

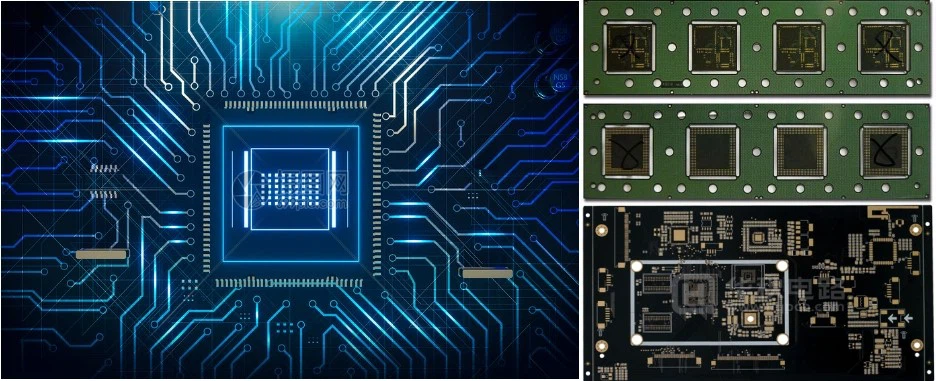

PCB Factory

Atlantic Technology Co., Ltd. was established in March 2000 and is located in Southeast Asia (Vietnam, Malaysia, Thailand, Hong Kong), covering an area of over 400 acres. Since its establishment, the company has been focusing on the manufacturing and sales of double-layer and multi-layer high reliability printed circuit boards, and is one of the leaders in the Southeast Asian printed circuit board industry.

The company has been selected as an industry research institution for several consecutive years due to its significant comprehensive advantages in refined management, process improvement, technological innovation, concentration of major customers, and location advantages T. The Top 100 PCB Manufacturing Enterprises in the World and the Printed Circuit Industry Association (CPCA) released by Information. Ranked third among the top 100 PCB investment companies in Southeast Asia in 2022.

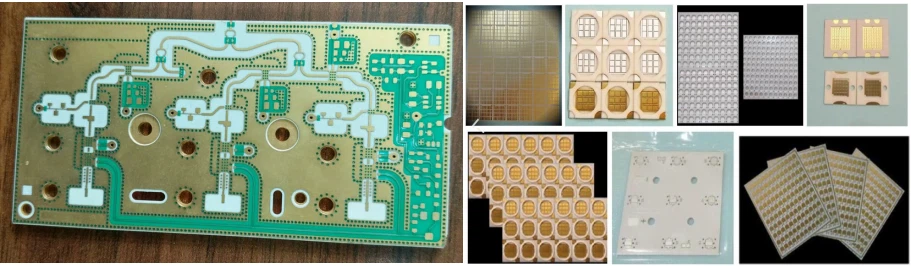

Phenolic paper substrate

1, Definition, characteristics, advantages, and common materials of paper substrates in PCB:

1.1 Definition

The paper substrate in PCB is a type of substrate material made from pulp or waste paper after special processing, used to manufacture circuit boards in electronic devices. Paper substrates generally have these names

Commonly known as phenolic paper substrate, cardboard, adhesive board, VO board, flame retardant board, red letter copper-clad board, 94V0, television board, color TV board, etc. Generally, phenolic resin is used as the adhesive. Wood pulp fibers are used

Wei paper is an insulating laminated material reinforced with materials.

1.2Characteristics

1.2.1. Conductivity: The paper substrate in PCB has certain conductivity by adding conductive agents or conductive fibers, which can conduct current and signals.

1.2.2. Mechanical strength: Paper substrates have high mechanical strength and durability through special manufacturing processes, and can withstand various stresses and vibrations in electronic devices.

Environmental sustainability: Due to the fact that paper substrates are mainly made of pulp or waste paper, they are more environmentally friendly and sustainable compared to traditional substrate materials, in line with the modern society’s requirements for environmental protection

Please.

1.3 Advantages

Low cost

cheapness

Low relative density

Can perform punching processing

Common materials include XPC, FR-1, FR-2, FE-3, 94V0, etc.

2. PCB in the field of electronics:

The paper substrate in PCB has a wide range of applications in the electronic field, mainly reflected in the following aspects:

2.1. Electronic products: Paper substrates can be used to manufacture various types of electronic products, such as smartphones, tablets, televisions, etc. As the basic material of circuit boards, it can provide circuits

Connection and support functions.

2.2. LED lighting: Paper substrates play an important role in the field of LED lighting. The circuit board in LED lamps is usually made of paper substrate, which has good heat dissipation performance And with conductivity, it can meet the needs of high brightness LED lights.

2.3. Smart Home: With the rapid development of smart homes, paper substrates have also been widely used in this field. It can be used to manufacture smart sockets, smart switches, and other devices to achieve home automation

Networking and intelligent control between residential devices.

composite substrate

The combustible material sample is ignited with a flame that meets the requirements, and the flame is removed after a specified time. The combustibility level is evaluated based on the degree of combustion of the sample, which is divided into three levels. The horizontal placement of the sample is the horizontal test method, which is divided into three levels: FH1, FH2, and FH3. The vertical placement of the sample is the vertical test method, which is divided into FV0, FV1, and VF2 levels.

There are two types of fixed PCB boards: HB board and V0 board.

HB board has low flame retardancy and is mostly used for single panels,

VO board has high flame retardancy and is commonly used for double-sided and multi-layer boards

This type of PCB board that meets the V-1 fire rating requirements is called FR-4 board.

V-0, V-1, V-2 are fire ratings.

The circuit board must be flame resistant and cannot burn at a certain temperature, only soften. The temperature point at this point is called the glass transition temperature (Tg point), which is related to the dimensional stability of the PCB board.

What is a high Tg PCB circuit board and the advantages of using a high Tg PCB?

When the temperature of a high Tg printed circuit board rises to a certain area, the substrate will transition from a “glass state” to a “rubber state”, and the temperature at this time is called the glass transition temperature (Tg) of the board. That is to say, Tg is the highest temperature at which the substrate maintains rigidity.

PCB What are the specific types of boards?

Divided from bottom to top by level:

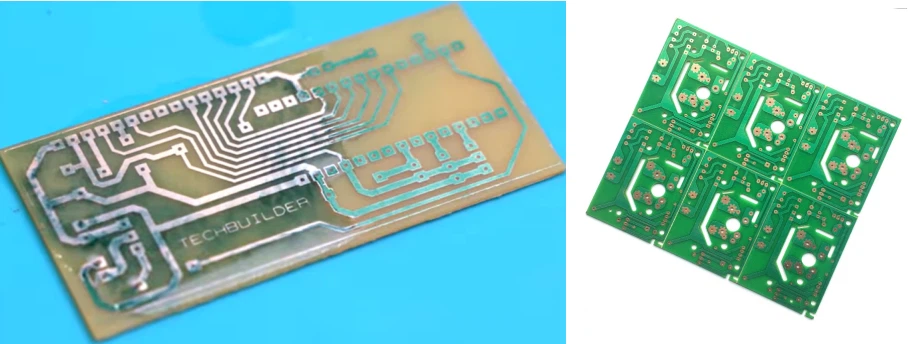

94HB - 94VO - 22F - CEM-1 - CEM-3 - FR-4

The detailed introduction is as follows:

94HB: Ordinary cardboard, not fire-resistant (the lowest grade material, die punched, cannot be used as a power board)

94V0: Flame retardant cardboard (die punched)

22F: Single sided semi fiberglass board (die punched)

CEM-1: Single sided fiberglass board (requires computer drilling and cannot be die punched)

CEM-3: Double sided semi fiberglass board (except for double-sided cardboard, which is the lowest end material of double-sided board, simple)

Double sided panels can use this material, which is 5-10 yuan/square meter cheaper than FR-4

FR-4: Double sided fiberglass board

2. PCB in the field of electronics:

The paper substrate in PCB has a wide range of applications in the electronic field, mainly reflected in the following aspects:

2.1. Electronic products: Paper substrates can be used to manufacture various types of electronic products, such as smartphones, tablets, televisions, etc. As the basic material of circuit boards, it can provide circuits

Connection and support functions.

2.2. LED lighting: Paper substrates play an important role in the field of LED lighting. The circuit board in LED lamps is usually made of paper substrate, which has good heat dissipation performance And with conductivity, it can meet the needs of high brightness LED lights.

2.3. Smart Home: With the rapid development of smart homes, paper substrates have also been widely used in this field. It can be used to manufacture smart sockets, smart switches, and other devices to achieve home automation

Networking and intelligent control between residential devices.

Epoxy fiberglass substrate

Epoxy Fiberglass Board (EPFB) refers to a composite formed by embedding or wrapping glass fiber materials into epoxy resin ,The material of the structure. Compared with ordinary glass fiber, epoxy glass fiber has high tensile strength, high elastic modulus, and impact resistance,It has excellent properties such as good energy, chemical stability, fatigue resistance, and high temperature resistance, and is widely used in aviation, aerospace, construction, and chemical industries Industries, agriculture, and other fields.

Advantages of epoxy resin

Epoxy resin has high bonding performance, good corrosion resistance, good processability, and excellent physical and mechanical properties

Capable of excellent toughness (the toughness of cured epoxy resin is about 7 times greater than that of cured phenolic resin), and it also undergoes curing shrinkage Low sex.

1.1Strong adhesion

The bonding strength of epoxy resin adhesive ranks among the top in synthetic adhesives because of the strong polar groups such as hydroxyl and ether bonds

Strong adhesion force is generated between epoxy molecules and adjacent interfaces; Epoxy groups react with metal surfaces containing active hydrogen to generate strong chemical reactions key.

1.2 Low curing shrinkage rate

No small molecules are generated during curing, resulting in high density and low shrinkage rate during curing. Shrinkage rate of epoxy resin adhesive in adhesives

The smallest, which is also one of the reasons for the high bonding strength of epoxy resin adhesive curing. For example, phenolic resin adhesive: 8-10%;Organic silicone resin adhesive: 6-8%; Polyester resin adhesive: 4-8%; Epoxy resin adhesive: 1-3%. If the shrinkage rate of epoxy resin decreases after adding fillers

0.1~0.3%, with a thermal expansion coefficient of 6.0X10-51 E-5in/in-F. [5]

1.3 Good chemical resistance and stability [2]

Ether groups, benzene rings, and fatty hydroxyl groups in the curing system are not easily corroded by acids and bases. In seawater, petroleum, kerosene, 10% H2S04

10% HCl, 10% HAc, 10% NH3, 10% H3PO4, and 30% Na2C03 can be used for two years; And in 50% H2SO4 and 10% HNO3Soak at room temperature for six months and soak in 10% NaOH (100 ℃) for one month, and the performance remains unchanged. [3]

1.4Excellent electrical insulation

The breakdown voltage of epoxy resin is greater than 35kv/mm.

1.5Good process performance

Can be miscible with various resins, easily soluble in solvents such as alcohol, acetone, toluene, etc., and can be easily cured and molded at room temperature. Product ruler,Stable size, good durability, and low water absorption rate.

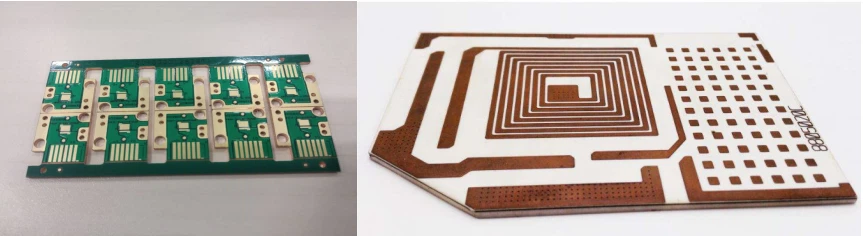

Metal substrate

A metal substrate consists of three parts: a circuit layer (copper foil), an insulating dielectric layer, and a metal substrate. A metal substrate is used as the base plate, with an insulating dielectric layer attached to the surface, forming a conductive circuit together with the copper foil on the substrate. It has the advantages of good heat dissipation and mechanical processing performance. Currently, the most widely used are aluminum and copper substrates.

1. Materials and Thermal Conductivity

Sliton ceramic substrate is made of ceramic material, which is an inorganic material with high thermal conductivity and strong ability to conduct and dissipate heat. The thermal conductivity of alumina (Al2O3) is 25-35w/m.k, the thermal conductivity of aluminum nitride (AlN) is 170-230w/m.k, and the thermal conductivity of silicon nitride (Si3N4) is 80-100w/m.k.

The base material of ordinary PCB is insulating material, with low thermal conductivity and weak heat conduction and dissipation ability. The thermal conductivity of FR-4 is 0.3-0.4 w/m.k

The substrate of a metal substrate is a metal material with high thermal conductivity, while the thermal conductivity of an aluminum substrate is 0.7-3w/m.k. The thermal conductivity of copper substrate is 300-400w/m.k, mainly used for car headlights, taillights, and drones. However, copper is expensive, costly, and has poor insulation properties Author: Sliton Ceramic Circuit Board

2. Electrical performance and high-frequency performance

Ceramic substrates have high dielectric constant and dielectric loss, making them excellent electrical performance in high-frequency circuits. Dielectric constant of alumina (Al2O3): 9-10, dielectric loss: 3-10; The dielectric constant of aluminum nitride (AlN) is 8-10, and the dielectric loss is 3-10; The dielectric constant of silicon nitride (Si3N4) is 8-10, and the dielectric loss is 0.001-0.1.

The dielectric constant and dielectric loss of ordinary PCB boards are relatively low, resulting in poor electrical performance in high-frequency circuits. The dielectric constant of PCB is 4.0-5.0, and the dielectric loss is 0.02-0.04

The dielectric constant and dielectric loss of metal substrates are relatively low, and they also have good electrical performance in high-frequency circuits. The dielectric constant of copper substrates is 3.0-6.0, and the dielectric loss is 0.01-0.03. The dielectric constant of aluminum substrates is 2.5-6.0, and the dielectric loss is 0.01-0.04. Author: Sliton Ceramic Circuit Board

3. Mechanical strength and reliability

Ceramic substrates have high mechanical strength and bending resistance, as well as high reliability and stability in high-temperature and harsh environments. The mechanical strength of alumina (Al2O3) ranges from 300Mpa to 350Mpa, aluminum nitride (AlN) ranges from 300Mpa to 400Mpa, and silicon nitride (Si3N4) ranges from 600Mpa to 800Mpa

The mechanical strength of ordinary PCBs is relatively low, and they are easily affected by factors such as temperature and humidity, resulting in reduced reliability in high temperature and humid environments. The mechanical strength of ordinary PCB ranges from 8Mpa to 500Mpa,

The mechanical strength of metal substrates is high, and electronic products have high heat dissipation and electromagnetic shielding during operation. The mechanical strength of copper substrates is 600